Ingenious Strategies to Fillet Weld Assessment and Screening: Enhancing Weld Quality and Compliance Specifications

In the realm of welding, the quality and honesty of fillet welds play an essential function in guaranteeing the architectural strength and dependability of various commercial parts. With the continuous drive for enhanced effectiveness and compliance with strict criteria, the expedition of innovative approaches to fillet weld examination and testing has come to be vital.

Advanced Non-Destructive Testing Techniques

Utilizing advanced modern technologies, progressed non-destructive testing approaches play a vital role in making certain the stability and quality of fillet welds. These methods, such as phased variety ultrasonic testing (PAUT) and magnetic bit screening (MPT), offer thorough insights into the weld's inner structure without triggering any kind of damage to the product. PAUT, for example, utilizes several ultrasonic components to examine the weld from numerous angles, providing a detailed visualization of possible defects like lack of blend or cracks.

Similarly, MPT works in detecting surface-breaking flaws by using a magnetic field and iron bits to the weld location. This approach is particularly useful for identifying discontinuities that may endanger the weld's stamina. By utilizing these advanced non-destructive testing methods, weld assessors can properly assess the quality of fillet welds, making sure conformity with sector criteria and laws. The capacity to discover problems beforehand not only enhances weld top quality but also prevents costly rework or failures in architectural honesty, underscoring the significance of these innovative screening strategies in welding examinations.

Robotics and Automation in Evaluation

The integration of robotics and automation has actually reinvented the evaluation process for fillet welds, boosting efficiency and precision in high quality assessment. Robotics supply exact control and repeatability in inspecting welds, making certain dependable and constant results. Automated systems can be configured to follow certain inspection courses, ensuring thorough protection of welds and reducing the danger of human mistake.

Robot inspection systems furnished with innovative sensors can discover and determine weld attributes with high precision, offering comprehensive information for evaluation. These systems can recognize defects such as cracks, lack of combination, and porosity, making it possible for prompt corrective actions to be taken. Furthermore, robotics and automation enable real-time information collection and evaluation, giving instant comments to operators and promoting quick decision-making processes.

Furthermore, the usage of robotics and automation in fillet weld evaluation enhances total performance by reducing inspection times and enhancing examination throughput. By streamlining the inspection process, producers can guarantee weld quality and compliance standards are fulfilled efficiently, ultimately resulting in set you back savings and enhanced item top quality.

Making Use Of Artificial Intelligence for Evaluation

Synthetic knowledge plays a critical role in improving the performance and accuracy of evaluation in fillet weld inspection procedures. AI formulas can rapidly refine substantial quantities of information from weld assessments, discovering problems or incongruities that may be testing to identify with the naked eye.

Furthermore, AI systems can pick up from past inspection data, consistently improving their capability to recognize potential problems and inconsistencies in fillet welds. This adaptive knowing ability boosts the overall top quality control process, websites lowering the probability of human mistake and guaranteeing that welds meet the called for standards. By incorporating expert system into fillet weld analysis, industries can accomplish greater degrees of performance, uniformity, and conformity in their assessment techniques.

Portable Tools for On-Site Evaluation

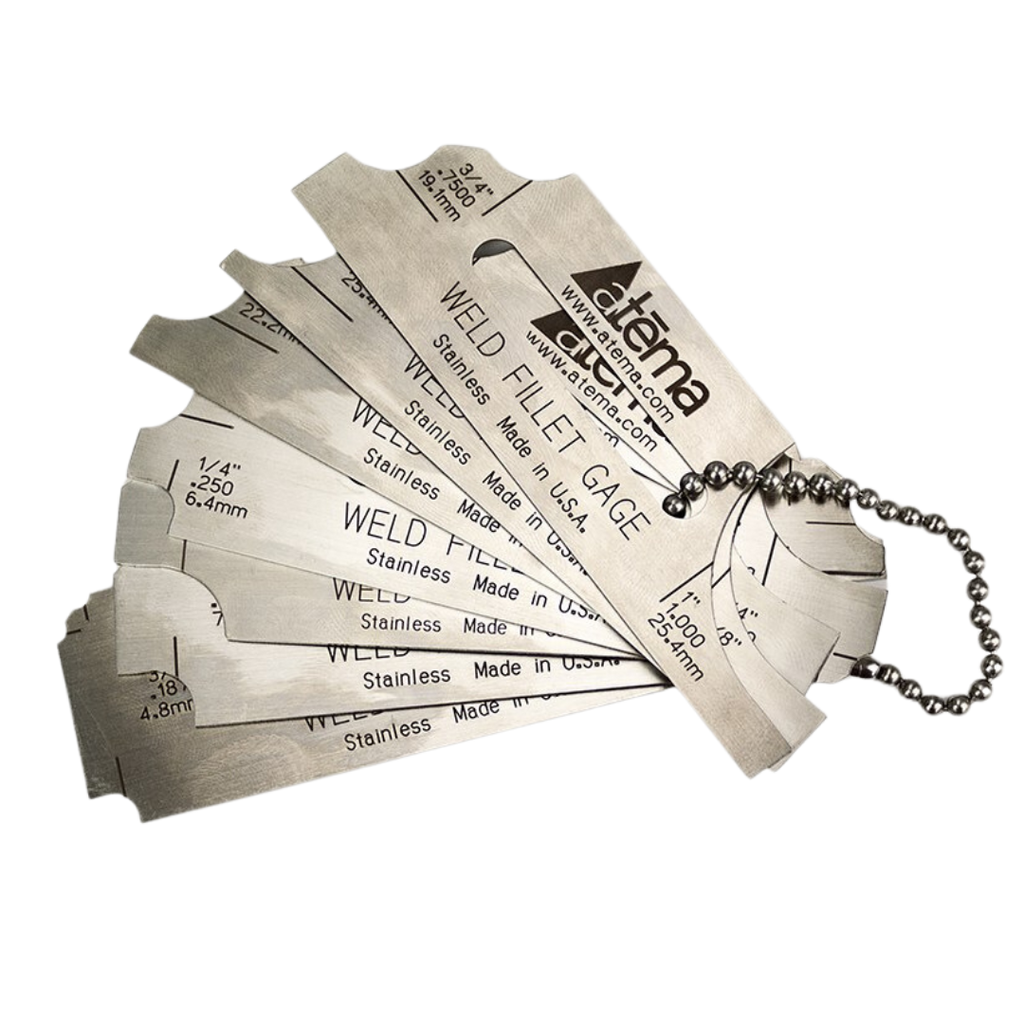

Enhancing field assessment performance, the fostering of mobile tools revolutionizes on-site evaluation processes for fillet welds. These tools provide versatility and benefit, enabling examiners to conduct extensive assessments in numerous areas, consisting of remote or difficult atmospheres. Portable tools such as ultrasonic screening tools, magnetic fragment examination tools, and digital radiography systems offer real-time data and high-resolution imaging capabilities, making it possible for fast decision-making get redirected here and instant feedback on weld top quality.

One substantial advantage of portable devices is their capability to improve evaluation treatments, lowering downtime and boosting general performance - Gauge Fillet Weld. Examiners can quickly move these tools to various task sites, removing the requirement for carrying heavy equipment or components to off-site facilities. In addition, the mobility of these tools advertises cost-effectiveness by lessening transportation expenditures and speeding up assessment timelines

In addition, the use of mobile tools for on-site inspection advertises positive quality assurance procedures, as inspectors can without delay determine and address any type of potential welding flaws or discrepancies. By including these innovative modern technologies into on-site wikipedia reference examination methods, welding specialists can guarantee conformity with industry requirements and boost weld quality, inevitably leading to enhanced architectural integrity and security in various welding applications.

Combination of Information Management Solution

Having enhanced on-site inspection processes through the use of mobile devices, the next stage includes the seamless assimilation of data monitoring systems to additionally improve performance and data evaluation abilities in fillet weld evaluation and screening. By integrating information administration systems right into the evaluation procedure, organizations can enhance data collection, storage space, and analysis. This assimilation enables real-time surveillance of weld high quality, prompt identification of defects, and punctual decision-making to correct any kind of issues that might arise during the inspection process.

Information management systems play a critical function in systematizing evaluation information, facilitating simple access for licensed personnel, and making sure information integrity and protection. Through the combination of these systems, examiners can create extensive records, track historic information for trend analysis, and improve overall process effectiveness. Furthermore, the assimilation of data monitoring systems makes it possible for smooth interaction in between various stakeholders involved in the assessment procedure, fostering collaboration and improving general quality assurance actions. Eventually, the combination of data management systems serves to elevate the standards of fillet weld inspection and screening, ensuring conformity with sector guidelines and improving weld high quality.

Final Thought

In final thought, innovative strategies to fillet weld examination and testing have actually considerably boosted weld top quality and compliance criteria. Advanced non-destructive testing methods, robotics, automation, fabricated intelligence, mobile devices, and information management systems have actually reinvented the way weld inspections are performed. By using these technologies, markets can ensure that welds fulfill the required top quality standards and laws, eventually improving general performance and safety in welding procedures.

Having actually enhanced on-site examination procedures through the utilization of mobile tools, the following phase involves the smooth combination of information administration systems to further improve efficiency and information analysis capacities in fillet weld assessment and testing. Inevitably, the integration of information management systems offers to raise the criteria of fillet weld assessment and screening, making sure compliance with market regulations and improving weld quality.